To keep your pit portable conveyors in top condition and prevent costly breakdowns, you need practical maintenance tips for pit portable conveyors. This guide will walk you through the most effective strategies for regular inspections, lubrication, belt tension adjustments, and more.

Key Takeaways

- Regular inspections and maintenance are essential for identifying potential issues early, ensuring consistent production flow and extending the lifespan of conveyor systems.

- Proper lubrication practices and belt tension adjustments are critical to preventing wear and premature failure, ensuring smooth operations of conveyor systems.

- Proactive component replacement, effective cleaning strategies, and thorough training for operators are key to maintaining conveyor efficiency and safety.

Regular Inspections for Optimal Conveyor Systems Performance

Routine inspections on conveyor systems help identify wear, misalignment, and other potential issues early. These inspections are the first line of defense against unexpected breakdowns that could disrupt your production flow. Spotting potential problems before they escalate allows for scheduling maintenance during planned downtimes, avoiding costly interruptions. It is crucial to maintain the integrity of the belt carcass during these inspections to ensure effective and long-lasting repairs.

Regular maintenance minimizes unexpected breakdowns and ensures consistent production flow. Consistency in production is vital; it not only meets deadlines but also maintains the quality of the product being transported. Inspections should be thorough, covering all components of the conveyor system, and should be conducted at regular intervals to ensure no detail is overlooked. The role of the tail pulley in maintaining proper belt tension is critical, as inadequate tension can lead to material spillage and accelerated wear on components.

Prioritizing regular inspections and maintenance enhances the efficiency and lifespan of your pit portable conveyors. This proactive approach not only improves efficiency but also extends the operational life of your equipment, providing a better return on investment.

Proper Lubrication Practices

Lubrication is fundamental for maintaining conveyor systems. It helps to extend the operational lifespan of conveyor systems by keeping components clean and well-lubricated. Adequate lubrication of all moving parts reduces friction and wear, preventing premature failure of critical components.

Lubrication is fundamental for maintaining conveyor systems. It helps to extend the operational lifespan of conveyor systems by keeping components clean and well-lubricated. Adequate lubrication of all moving parts reduces friction and wear, preventing premature failure of critical components.

Using the correct lubricant type avoids insufficient lubrication or potential damage. Adhering to the manufacturer’s recommended lubrication schedule prevents over- and under-lubrication issues. It’s important to clean lubrication points before applying grease or oil to prevent contamination. Using proper tools, such as grease guns for bearings and specialized oilers for motors, ensures effective lubricant application.

Regular lubrication is fundamental to keeping your conveyor system running smoothly. Neglecting proper lubrication can lead to significant operational issues, including increased friction, wear, and eventual system failure.

Belt Tension Adjustment

Proper belt tension avoids issues such as belt slippage, spillage, and premature failure. Improper belt tension can cause material spillage, a damaged belt, belt slippage, and accelerated wear. Additionally, excessive belt sag can cause premature failure on the wing pulley due to improper sealing against the skirting. These issues not only interrupt operations but can also lead to more serious mechanical failures down the line.

Periodic inspections ensure proper tension and prevent costly operational issues. Using a tension gauge can help achieve accurate adjustments of belt tension. Adjust belt tension according to the manufacturer’s specifications for optimal performance. Environmental factors like temperature and humidity can impact belt tension and should always be considered. Using proper fasteners, such as Flexco Repair Fasteners, is crucial for maintaining belt tension and ensuring reliable repairs.

Correct belt tension maintains the efficiency and longevity of your belting conveyor system. Regular checks and adjustments are essential in preventing undue strain and ensuring smooth operation.

Cleaning and Debris Management

Keeping conveyor belts clean avoids material buildup and operational inefficiencies. Thorough cleaning at the beginning and end of each day prevents interference with conveyor operations. Cleaning protocols should include removing debris from the belt surface to ensure smooth operation and prevent damage.

Keeping conveyor belts clean avoids material buildup and operational inefficiencies. Thorough cleaning at the beginning and end of each day prevents interference with conveyor operations. Cleaning protocols should include removing debris from the belt surface to ensure smooth operation and prevent damage.

Regular cleaning helps prevent friction-related issues, such as slippage, which can disrupt the flow of materials on the conveyor. Regular cleaning keeps the conveyor system running efficiently and avoids unnecessary wear and tear.

Component Replacement Strategy

A proactive approach to component replacement, like fasteners, rollers, and scrapers, minimizes downtime and maximizes conveyor lifespan. High-quality components and fasteners closer, such as Flexco Repair Fasteners, ensure reliable repairs and enhance the conveyor system’s durability. Additionally, selecting fasteners that are compatible with the maximum belt thickness is crucial for effective repairs. Conveyor belt rip repair is essential for maintaining optimal performance.

Proper installation techniques, like using templates for fastener placement and ensuring all bolts are grind bolt end flush after installation, are critical for effective repairs. Address component failures, such as a belt roller causing a rip repair, immediately to prevent extended downtime with turtle fasteners, rip repair fasteners, and three bolt fasteners. To ensure success, it is essential to apply fasteners correctly unlike regular splice installation. Quick and easy installation of easy rip repairs can significantly enhance the efficiency of the repair process, especially when installing rip repair fasteners, extra long bolts, and bolt solid plate fasteners. The range of available belt thicknesses for Flexco Repair Fasteners, from ¼ to 1 ¼” thick (6mm to 32mm), ensures compatibility with various belt sizes. Our company offers rip repair kits to further assist in these repairs, including a complete splice option.

A proactive stance on component replacement saves significant time and money. By ensuring all parts are in top condition, you can avoid unexpected failures and keep your conveyor systems running smoothly, including motor replacement.

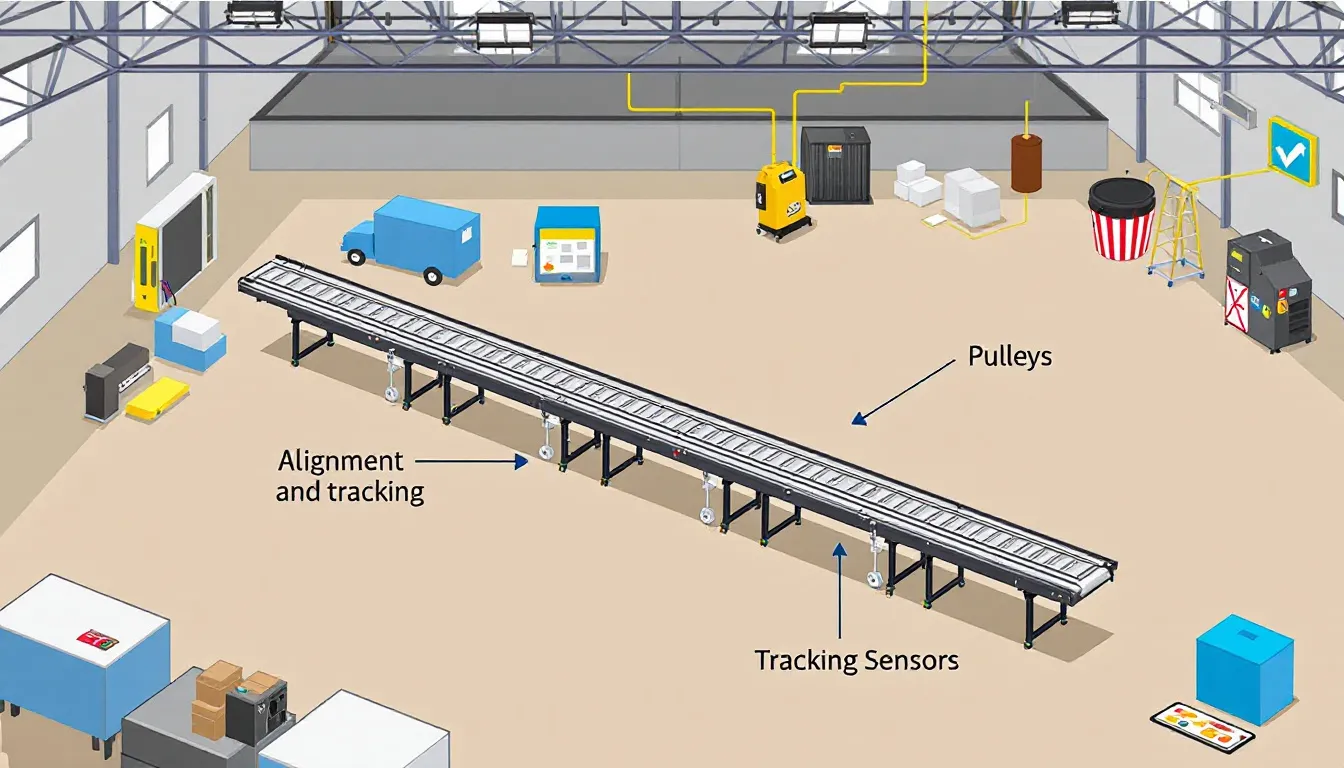

Alignment and Tracking Maintenance

Regular alignment checks prevent long-term damage to the conveyor belt system. Misalignment of belt rollers can lead to uneven wear on the belt, thereby shortening its lifespan. Tracking devices enable early detection of alignment issues, minimizing downtime.

Regular alignment checks prevent long-term damage to the conveyor belt system. Misalignment of belt rollers can lead to uneven wear on the belt, thereby shortening its lifespan. Tracking devices enable early detection of alignment issues, minimizing downtime.

Regular alignment and tension checks enhance the belt’s longevity. A common result of poor alignment is increased wear on the belt, which can lead to premature failure. Ensuring proper maintenance of alignment and tracking, as well as addressing belt misalignment, is essential to the overall health of the conveyor system.

Load Management Techniques

Balanced material flow prevents localized stress points and premature conveyor belt failure. Putting stress on monitoring systems detects uneven loading on conveyor belts and allows for real-time adjustments. Excessive loading on a conveyor belt can cause significant stretching or permanent deformation of the belt material.

The lifespan of shorter conveyor belts is negatively impacted by frequent impacts at loading points. Effective load management maintains the structural integrity and efficiency of your conveyor systems.

Effective Use of Belt Cleaners

Conveyor belt cleaners remove product carryback and prevent falling material. Belt cleaners help mitigate issues such as excessive build-up, wear on idlers and pulleys, misalignment, and create a safer work environment. Effectively controlling carryback requires installing a proper belt cleaning system. Regular maintenance of this system is also crucial.

Sensors and monitoring systems identify uneven loading, facilitating timely adjustments to carryback issues. Material carryback occurs when materials stick to the belt instead of being discharged, leading to maintenance challenges. Belt cleaners are versatile and can effectively handle a variety of materials, including sticky and abrasive substances.

Compact and easy to install, belt cleaners are suitable for spaces where traditional scrapers may not fit. Maintaining and installing belt cleaners properly prevents material buildup and ensures the longevity of your conveyor systems.

Preventative Maintenance Checklist

Preventative maintenance prevents common issues, improves safety, minimizes downtime, and extends equipment life. Regular conveyor belt inspections include checking for signs of wear, ensuring proper tension, and maintaining cleanliness. Documenting maintenance activities helps in tracking recurring problems and facilitates timely resolutions. Additionally, understanding the hours of operation can help in scheduling maintenance more effectively to avoid unexpected downtimes.

Preventative maintenance prevents common issues, improves safety, minimizes downtime, and extends equipment life. Regular conveyor belt inspections include checking for signs of wear, ensuring proper tension, and maintaining cleanliness. Documenting maintenance activities helps in tracking recurring problems and facilitates timely resolutions. Additionally, understanding the hours of operation can help in scheduling maintenance more effectively to avoid unexpected downtimes.

A plan for emergency repairs minimizes downtime, highlighting the importance of readiness in complex maintenance situations. Effective preventative maintenance requires proper tools and maintenance tools and techniques, ensuring all the tools are readily available. This includes using power tools and bolt breakers to ensure the integrity of the belt during repairs.

Incorporating a preventative maintenance checklist ensures your conveyor systems operate efficiently and remain in optimal condition.

Training and Safety Protocols

Training operators enhances safety and efficiency by equipping them with essential conveyor operation knowledge. Using belt cleaners contributes to workplace safety by reducing hazards such as slippery floors caused by material carryback. Incorporating maintenance checklists into workflows helps improve efficiency and ensures all tasks are completed.

Training and safety protocols are vital for a well-maintained conveyor system. Well-trained operators and strict adherence to safety protocols lead to a safer and more efficient working environment.

Contacting Experts for Complex Issues

Consult professionals for maintenance issues exceeding your expertise, especially if the problem seems complicated. Consulting experts is crucial when facing maintenance problems outside your capabilities. Professional services provide rapid assistance during critical failures, ensuring the conveyor system is operational with minimal delay.

Ensure repairs are done correctly and safely by seeking expert assistance when in doubt. A reliable expert on call significantly impacts maintaining the efficiency of your conveyor systems.

Summary

In summary, proper maintenance of pit portable conveyors involves regular inspections, proper lubrication, maintaining belt tension, managing debris, replacing components timely, ensuring alignment and tracking, managing loads, using belt cleaners effectively, and following a preventative maintenance checklist. Training and safety protocols are also essential, alongside knowing when to call in experts for complex issues.

By implementing these maintenance tips, you can ensure your conveyor systems run efficiently, reduce downtime, and extend their operational lifespan. A well-maintained conveyor system is the backbone of any efficient operation, ensuring consistent productivity and safety.

Frequently Asked Questions

Why are regular inspections important for pit portable conveyors?

Regular inspections are crucial for pit portable conveyors because they help detect wear and misalignment early, preventing unexpected breakdowns and ensuring consistent production flow. Maintaining the integrity of the belt carcass during these inspections is essential to prevent damage and ensure the longevity of the conveyor system. This proactive approach ultimately enhances operational efficiency and reduces maintenance costs.

How does proper lubrication impact the lifespan of a conveyor system?

Proper lubrication significantly extends the lifespan of a conveyor system by reducing friction and wear on critical components, thereby preventing premature failure. This proactive maintenance measure is essential for optimal system performance.

What are the consequences of improper belt tension?

Improper belt tension can lead to material spillage, slippage, and accelerated wear, ultimately resulting in costly operational disruptions. Additionally, excessive belt sag can cause premature failure on the wing pulley due to improper sealing against the skirting, illustrating the critical role that wing pulleys play in the overall functionality and maintenance of belt conveyors. Ensuring correct tension is crucial for optimal performance and longevity.

Why is it important to manage debris on conveyor belts?

It is crucial to manage debris on conveyor belts to prevent material buildup that can cause operational inefficiencies and damage to the system. Regular maintenance ensures smooth operation and prolongs the lifespan of the conveyor.

When should you contact experts for conveyor maintenance?

Contact experts for conveyor maintenance when facing complex issues beyond your expertise or whenever the problem poses a risk of significant downtime. Their specialized knowledge ensures timely and effective solutions.