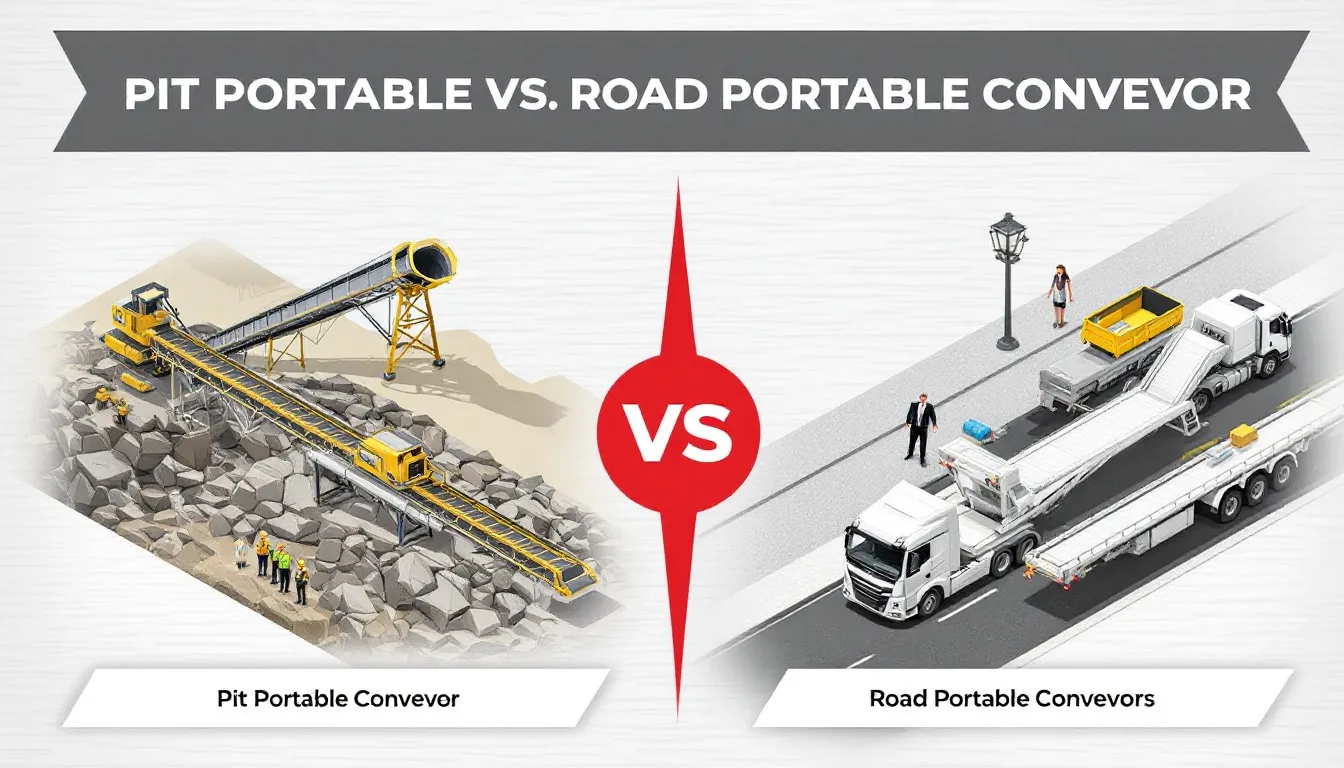

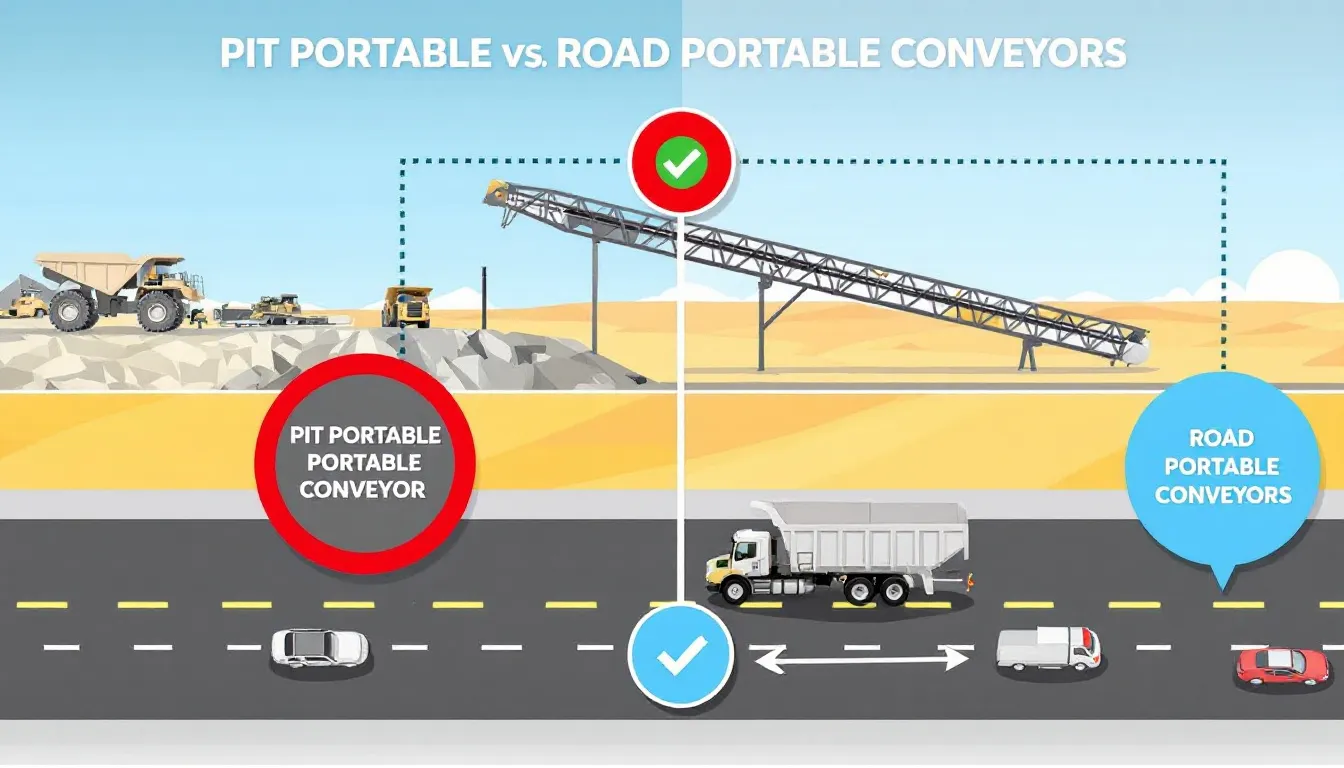

When choosing between pit portable conveyors vs. road portable conveyors, project requirements are crucial. Pit portable conveyors excel in stationary environments like quarries, boosting efficiency and cutting costs. Conversely, road portable conveyors offer mobility for jobs needing frequent relocations, such as road construction. This article dives into the key differences, pros, and applications of each to help you make an informed decision.

Key Takeaways

- Pit portable conveyors excel in localized material transport, maximizing efficiency in confined spaces like quarries, while road portable conveyors offer versatility for frequent relocation on public roads.

- Cost implications favor conveyor systems, which can reduce haulage costs by 30% to 75% compared to trucks, highlighting their economic benefits for large projects.

- Environmental advantages of conveyor systems include reduced dust and noise emissions, demonstrating their role in promoting a cleaner and more sustainable work environment.

Understanding Pit Portable Conveyors

Pit portable conveyors are built for localized material transport, making them perfect for projects in specific areas like quarries. The importance of belt widths in optimizing material transport efficiency cannot be overstated, as different belt widths can significantly impact the capacity and performance of conveyor systems. They are especially beneficial in heavy construction and mining projects because they can operate 24/7 with fewer workers compared to trucks.

They provide significant cost efficiency and lessen the advantage on staff and local communities compared to traditional trucking methods. Efficiency improvements in coal transportation using pit portable conveyors have been demonstrated, particularly through the use of regenerative conveyor designs that outperform traditional heavy haul trucks.

Mobility and Setup

A key feature of pit portable conveyors is their mobility and fast setup. They can be anchored with concrete blocks for stable and safe operation. Additionally, these conveyors can operate effectively over unstable ground, enhancing their adaptability.

These conveyors operate efficiently within confined spaces, allowing easy movement within a pit or quarry site, making them versatile range equipment.

Ideal Applications

Pit portable conveyors excel in environments like gravel and sand pits where quick and efficient material movement is needed. Easy unloading features contribute to efficient pit management, making these conveyors ideal for demanding environments. For instance, in gravel pits, they streamline material transfer from extraction points to processing areas, solving logistical challenges and minimizing downtime.

Capacity and Efficiency

Pit portable conveyors excel in capacity and efficiency. They maintain a consistent material flow with minimal downtime, significantly boosting material transport and reducing manpower needs.

In a fast paced environment like gravel pits, these belt conveyors handle large volumes of material, enhancing overall project efficiency.

Exploring Road Portable Conveyors

Road portable conveyors are designed for easy transport on public roads, featuring specialized axle and wheel configurations that meet road regulations. Certain models are equipped with brakes for legal road use. Their versatility makes them useful in various projects like construction sites, road building, and remote mining operations, where frequent relocation is necessary.

Considerations such as setup time, hydraulic systems, and power requirements are crucial for maximizing their efficiency in different project environments. Proper installation is also essential for maximizing efficiency and achieving long-term operational savings.

Design and Transportability

The design and transportability of road portable conveyors are essential for their functionality. These conveyors have axle and wheels configurations that improve their mobility on public roads, ensuring compliance with transport regulations. The importance of covers in protecting the conveyor belts during transport cannot be overstated, as they enhance durability and flexibility, particularly in demanding environments.

Adjustable axle placements optimize load distribution, enhancing stability during transit and reducing risks associated with road travel. This allows for a pivot in the approach to managing weight distribution effectively.

Versatility Across Projects

Road portable conveyors are highly versatile, suitable for various projects from construction and roadwork to remote mining operations. They reduce transportation costs and improve project timelines, which is particularly useful in remote construction projects where logistics are challenging. Fuel costs impact the scalability and maintenance of these conveyors. Additionally, road portable equipment enhances the efficiency of these operations. However, the market faces challenges due to driver shortages, as fewer younger individuals are entering the market for haul truck drivers while experienced drivers retire.

Operational Considerations

Operational considerations are vital when using road portable conveyors. These systems can greatly reduce material handling costs, especially in large construction projects. They operate continuously without needing additional permissions and avoid congested areas, minimizing delays and enhancing overall efficiency.

Key Differences Between Pit Portable and Road Portable Conveyors

Both pit portable and road portable conveyors enhance operational efficiency by enabling quicker material handling and reducing downtime. However, their main differences are in flexibility, cost implications, and environmental impact. The cost per ton of haulage can drop significantly, by up to 75%, when using overland conveyors instead of mining trucks in specific operations, highlighting the economic advantages of this alternative transport method.

Both pit portable and road portable conveyors enhance operational efficiency by enabling quicker material handling and reducing downtime. However, their main differences are in flexibility, cost implications, and environmental impact. The cost per ton of haulage can drop significantly, by up to 75%, when using overland conveyors instead of mining trucks in specific operations, highlighting the economic advantages of this alternative transport method.

Understanding these differences can help you choose the right conveyor system for your specific project needs. Conveyor systems provide a straight-line connection between the source and destination for efficient material transport.

Flexibility and Mobility

In terms of flexibility and mobility, pit portable conveyors are easily repositioned within confined spaces, while road portable conveyors can travel over public roads. This makes pit portable conveyors ideal for stationary projects, while road portable conveyors are better for projects needing frequent relocation.

Cost Implications

The cost implications of using each type of conveyor are substantial. While the capital cost of haul trucks is just over half that of building a conveyor system with the same capacity, conveyors can reduce the cost per ton of haulage by 30% to 75% compared to trucks. Overland conveyors can transport up to 15,000 tons per hour, and radial stackers can manage between 200 to 1,200 tons per hour, highlighting their efficiency and scalability.

Conveyor systems also have lower operational costs, transporting a ton of material at a quarter of the cost of trucks.

Environmental Impact

Conveyors typically offer a cleaner operation with less dust and spillage compared to trucks, moving materials almost twice as efficiently at speed and can carry materials effectively. Transfer conveyors, electrically powered motor conveying systems, achieve an energy efficiency of about 85%, contributing positively to environmental considerations.

They also generate significantly lower noise levels, contributing to a quieter and more sustainable work environment.

Choosing the Right Conveyor for Your Project

Choosing the right conveyor for your project requires a thorough evaluation of project requirements, site conditions, and long-term planning. Knowing the specific characteristics of materials, such as size and weight, and the importance of customizing the hopper to meet individual project needs, and factors like project logistics, type of material, distance, and terrain is crucial for optimizing material handling efficiency. Additionally, the length of the conveyor impacts its functionality and site-specific requirements.

Choosing the right conveyor for your project requires a thorough evaluation of project requirements, site conditions, and long-term planning. Knowing the specific characteristics of materials, such as size and weight, and the importance of customizing the hopper to meet individual project needs, and factors like project logistics, type of material, distance, and terrain is crucial for optimizing material handling efficiency. Additionally, the length of the conveyor impacts its functionality and site-specific requirements.

Assessing Project Requirements

Assessing project requirements is the first step in selecting the right conveyor. Road portable conveyors can be set up quickly, which is crucial for projects with tight schedules. The setup process often uses hydraulic systems for swift deployment, reducing downtime and improving operational efficiency. Support throughout the design, installation, and operational phases is essential to help clients achieve their production goals and successfully manage material handling projects.

Including future project requirements in the decision-making process ensures the selected conveyor system is sustainable.

Site Conditions and Constraints

Site conditions and constraints significantly influence conveyor selection. Challenges in a gravel pit include managing varying terrain and ensuring conveyor stability under heavy loads. The incline of the terrain can impact the choice of conveyor, as steep gradients may require specialized systems. Additionally, understanding whether the material is wet is crucial for selecting the appropriate conveyor system.

Knowing the physical layout and potential hazards of a site is crucial for selecting a suitable conveyor system.

Long-Term Planning

Long-term planning is essential for choosing a conveyor system that meets current and future project needs. Anticipating future demands ensures the selected system remains viable for extended use. Considering future expansions can influence the selection of a scalable conveyor system.

Thoughtful long-term planning aids in selecting conveyor systems that are efficient and adaptable to changing project needs.

Real-World Examples and Case Studies

Real-world example and case studies offer valuable insights into the benefits of each conveyor types and other types. Successful applications of modern conveyor systems in various projects highlight their importance in improving operational efficiency, offering low-impact solutions, safety, and reliability in material handling. Conveyors have fewer moving parts, leading to reduced risks of breakdowns and less downtime for repairs.

Additionally, the adaptability of conveyor systems plays a crucial role in enhancing efficiency. The versatility and portability of stacker conveyors in various work sites further emphasize their operational capacities and design features, making them suitable for diverse material handling needs.

Case Study: Gravel Pit Operation

A gravel pit operation successfully used pit portable conveyors to streamline material handling and enhance site productivity despite challenging terrain. Optimizing conveyor placement minimized material transport distances, solving logistical challenges and improving overall efficiency.

Case Study: Remote Construction Project

In a remote construction project, road portable conveyors were crucial for transporting materials over challenging terrain. These overland conveyors enabled efficient logistics, adapting well to the project’s challenging terrain and significantly enhancing efficiency. The materials were transported efficiently, ensuring the success of the project.

Using road portable conveyors led to significant cost savings, reducing both time and operational costs in the project.

Maintenance and Reliability

Maintaining conveyor systems is crucial to avoid costly breakdowns and ensure smooth operations. A detailed maintenance plan and regular inspections can significantly reduce unexpected breakdowns and prolong conveyor lifespan. Additionally, maintaining pulleys in conveyor systems is essential, as they play a critical role in both basic configurations like head and tail pulleys and more complex setups requiring additional torque.

Regular maintenance not only extends the life of the equipment but also improves safety and efficiency. Neglecting maintenance can lead to frequent breakdowns, increased downtime, and higher operational costs, ultimately affecting overall project efficiency. The use of rubber in the manufacturing of industrial conveyor belts is also vital, as it enhances the durability and flexibility of the belts, contributing to the creation of long-lasting conveyor systems.

Routine Maintenance Tips

Routine maintenance is vital to keep conveyors in optimal condition. Daily inspections should check for debris accumulation and unusual noises during job operation to prevent disruptions.

Frequently lubricating moving parts helps prevent wear and tear on bearings, significantly enhancing reliability and lifespan.

Troubleshooting Common Issues

Troubleshooting common issues like belt slippage can often be resolved by adjusting tension. Regularly checking and adjusting the tension ensures optimal performance and mitigates belts slippage.

Long-Term Durability

The durability of materials used in heavy duty conveyor construction is essential for long-term reliability and minimizing downtime. Long-term durability is crucial for the reliable operation of both pit portable and road portable conveyors, ultimately affecting overall project efficiency.

Summary

In summary, both pit portable and road portable conveyors offer unique advantages and are suitable for different project needs. Understanding the specific characteristics of each type, assessing project requirements, and considering long-term planning are essential for selecting the right conveyor system. By making informed decisions, you can enhance efficiency, reduce costs, and ensure the success of your material handling projects.

Frequently Asked Questions

What are the main advantages of using pit portable conveyors?

Pit portable conveyors provide significant cost efficiency and can operate continuously in confined spaces, requiring a smaller workforce compared to trucks. This leads to reduced community impact, making them an excellent choice for mining and quarry operations.

How do road portable conveyors enhance project efficiency?

Road portable conveyors significantly enhance project efficiency by allowing quick setup and easy transport to various sites, which reduces transportation costs and accelerates project timelines. Their mobility ensures minimal downtime, enabling continuous workflow.

What are the cost implications of using conveyors over haul trucks?

Using conveyors can result in a cost reduction of 30% to 75% per ton in haulage compared to haul trucks, despite their higher initial investment. Additionally, conveyors tend to have lower long-term operational costs, making them more economical in the long run.

How do conveyors impact the environment compared to trucks?

Conveyors positively impact the environment by offering cleaner operations with reduced dust, lower noise pollution, and improved energy efficiency compared to trucks. This makes them a more sustainable choice for transporting materials.

What maintenance practices can enhance the reliability of conveyor systems?

Implementing routine maintenance, such as daily inspections, lubrication of moving parts, and regular tension adjustments, is essential for enhancing the reliability and lifespan of conveyor systems. Consistent attention to these practices will help ensure optimal performance.