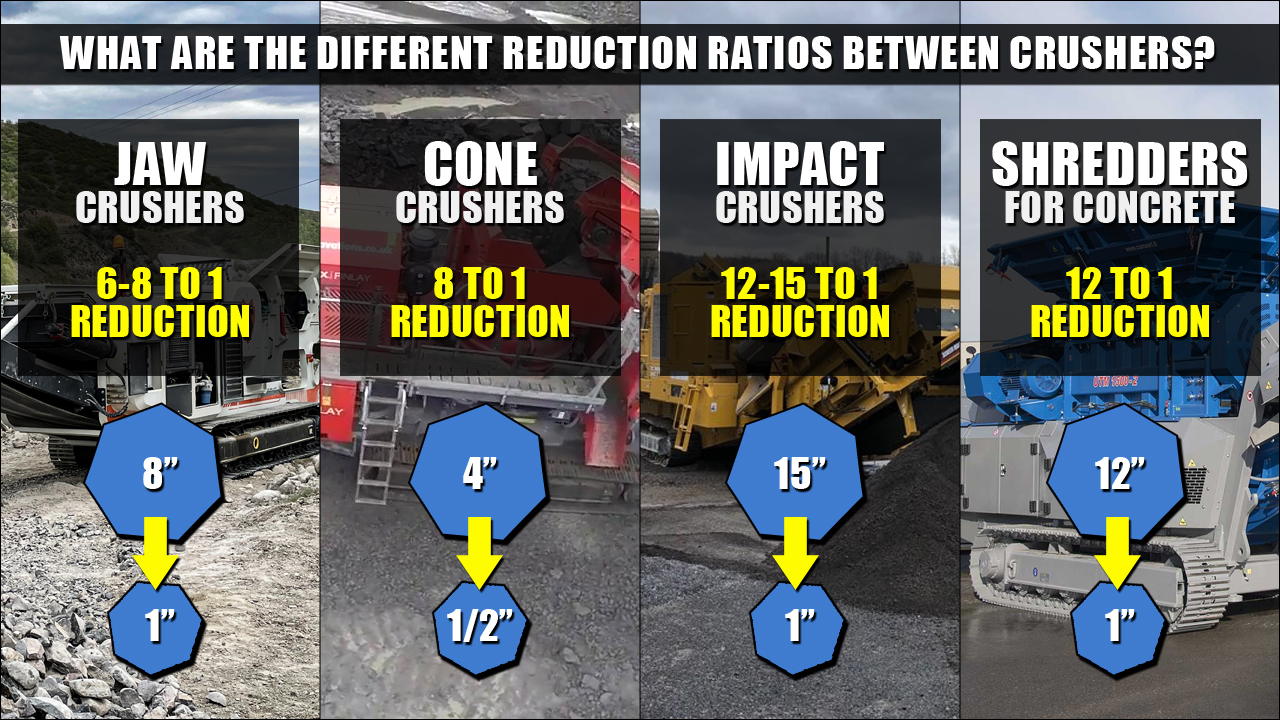

YES! So let’s discuss the three basic types of crushers …and one shredder!

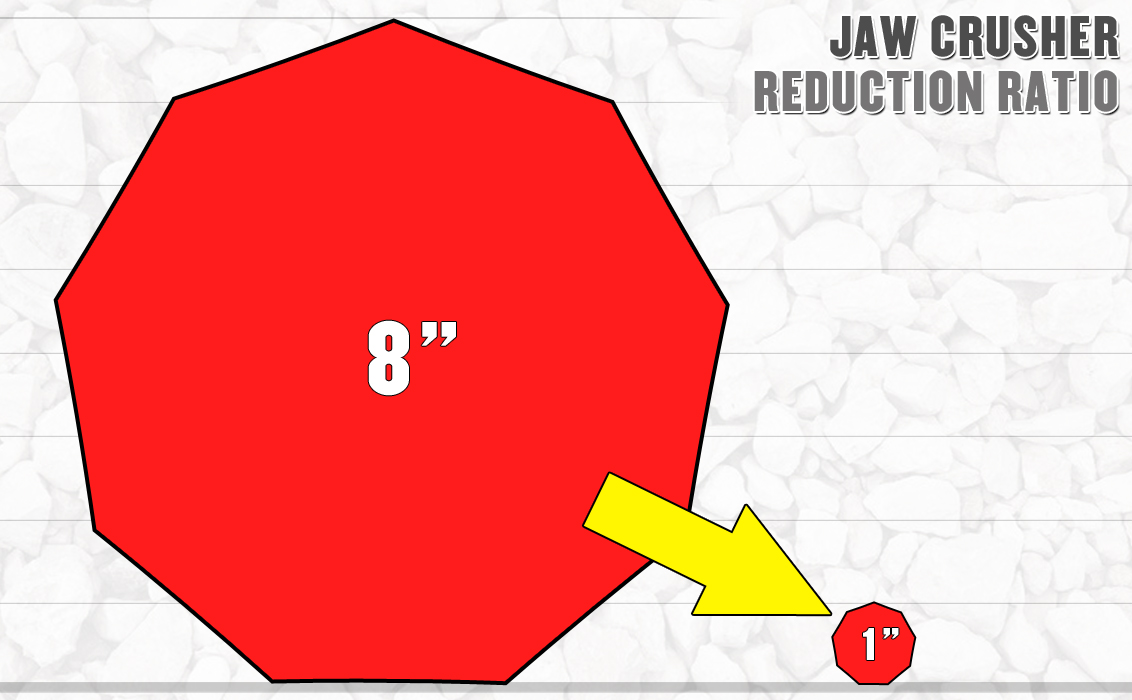

Jaw Crushers:

The typical rule of thumb is 6-8 to 1 reduction. This means a piece of concrete 6” to 8” can be crushed down to 1”. On a larger crusher you can typically only crush down to 2-1/2” to 3” but the pieces fed can be approximately 15” to 24”.

On the small jaw crushers we sell, customers are experiencing a greater product reduction by only using our jaw crusher as both a primary and secondary crusher. A 1” minus product can be achieved this way.

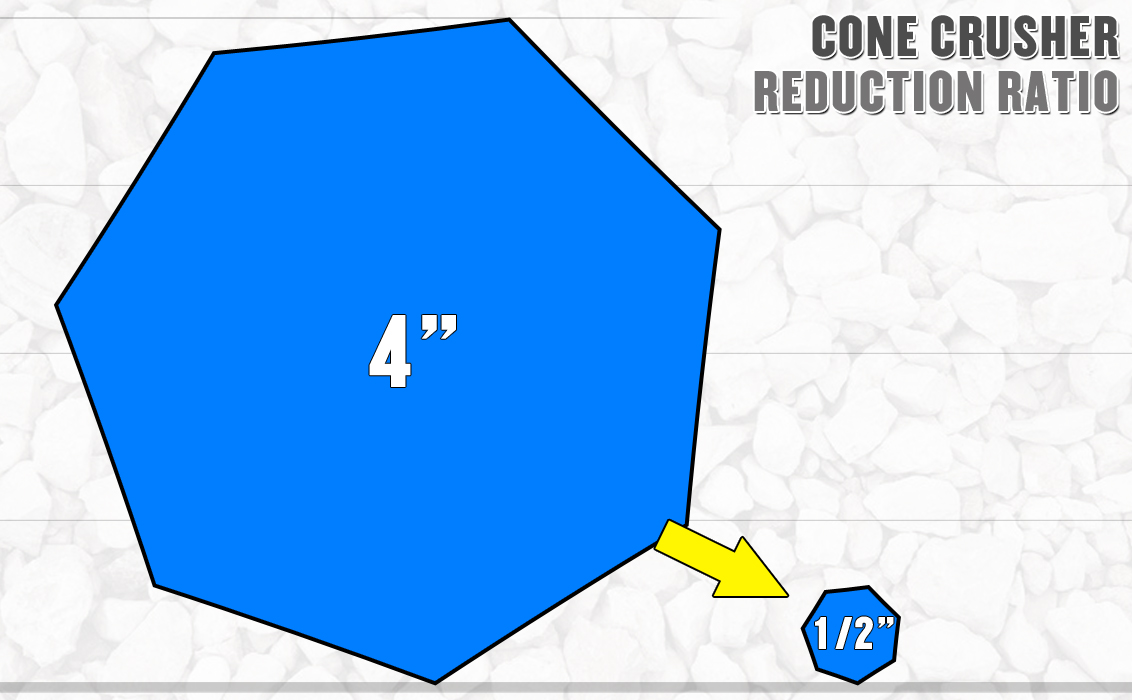

Cone Crushers:

Cone crushers are considered a secondary crusher. You shouldn’t feed any material larger than 4” into one, but it can yield an 8 to 1 reduction. This means we can go down to ½” and even 3/8” depending on the feed size. Cone crushers are similar to jaw crushers in that they are relatively low wear.

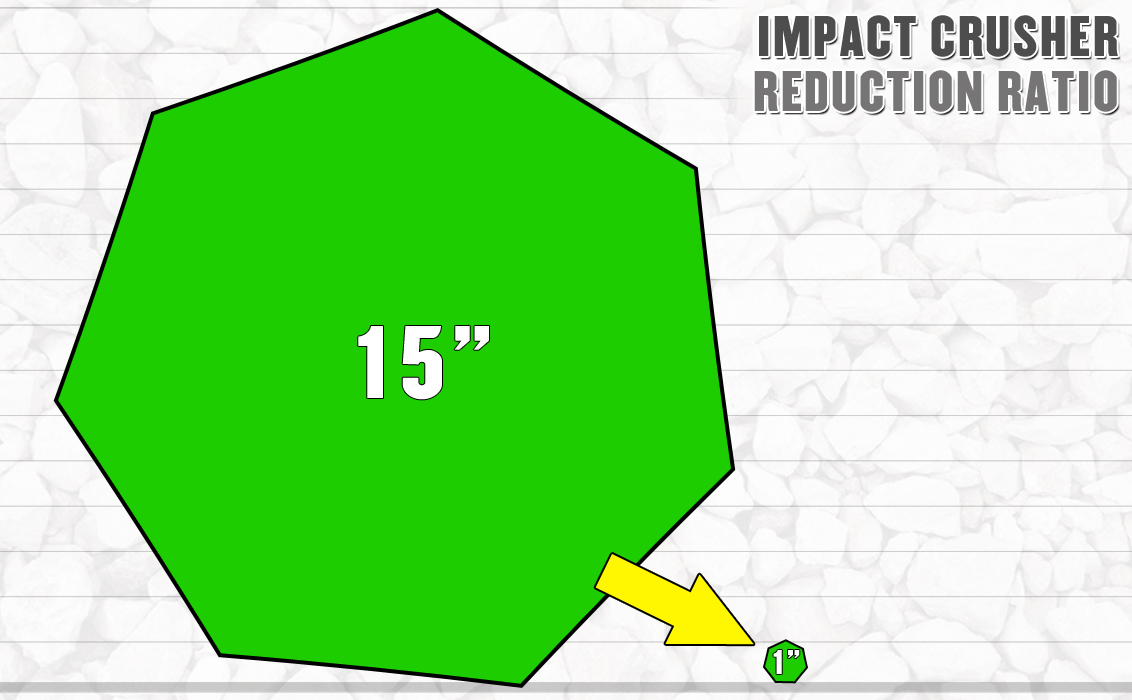

Impact Crushers:

Impact crushers can yield a considerably higher reduction than jaws or cones, from 12-15 to 1. This means one can take a 12” or 15” piece and reduce it to 1”. This is a large reduction but there is a cost for it. First, the wear on the blow bars is tremendous and they must be changed regularly. They are not cheap. Second, impact crushers create a ton of fines. Although, some want extra fines others do not. Impact crushers also create a great deal of dust due to the high speed rotor.

Concrete/Asphalt Shredders:

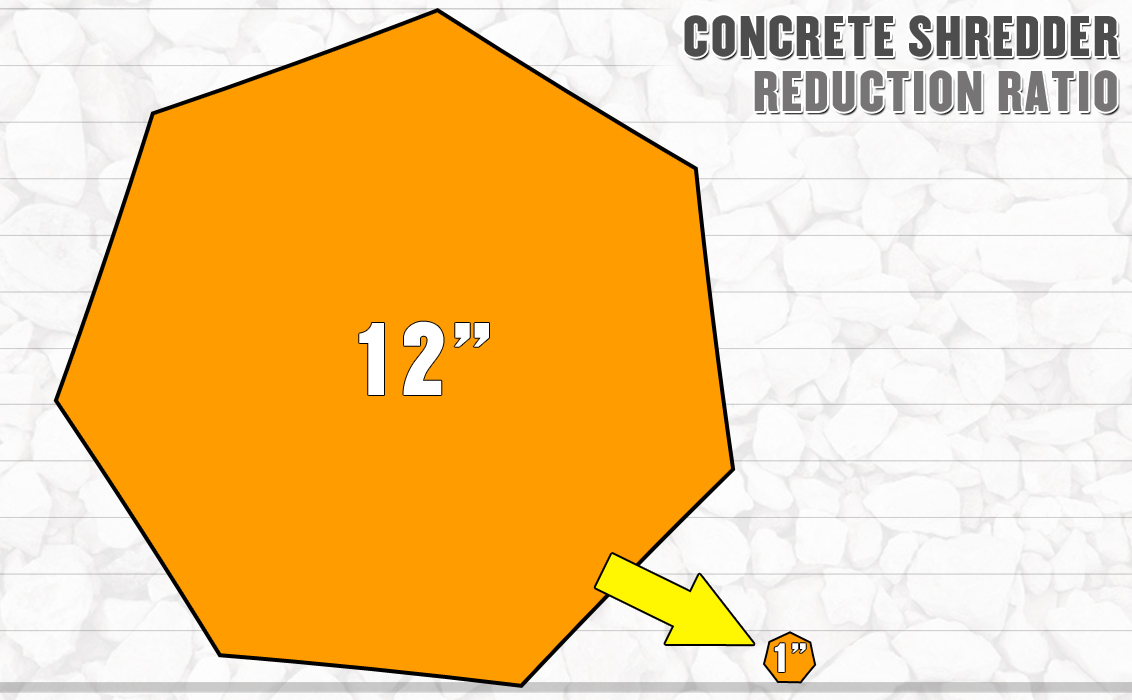

Although shredders are not crushers, they can make a similar product and are becoming very popular, so we must discuss them. The reduction is 12 to 1, like an impact crusher, but with minimal wear and dust, unlike an impact crusher. Concrete Shredders are best used as primary shredders as the finished material is approximately 3” minus. The exception is the Cams APR1000. This asphalt shredder is designed to take 5’ pieces of asphalt and RAP and reduce it to ½” material. This unique patented machine has both a primary and secondary shredder; and additionally, is equipped with a 17’ long shaker screen. In our opinion, it is the most impressive machine we have ever seen to crush/shred asphalt, which is saying a lot having sold equipment for 40+ years!

Very rarely do people discuss product reduction ratios, but it is extremely important to know the capabilities of the different reduction technologies.

If you'd like to learn more on Crusher types, see our other articles like "What is a Jaw Crusher", "What is an Impact Crusher", and "What Type of Crusher is Best?"