Jaw Crushers are considered a primary crusher and designed to crush hard rock, concrete, brick, and block. These crushers are the most economical to operate, and have a product reduction rate of 6-8 to 1. In a typical operation, jaw crushers crush the large pieces then the material is screened and material that is not the proper size falls into a cone crusher to yield a finished product. Small/Mini jaw crushers will yield a finished product in one step, but should never be used for hard rock.

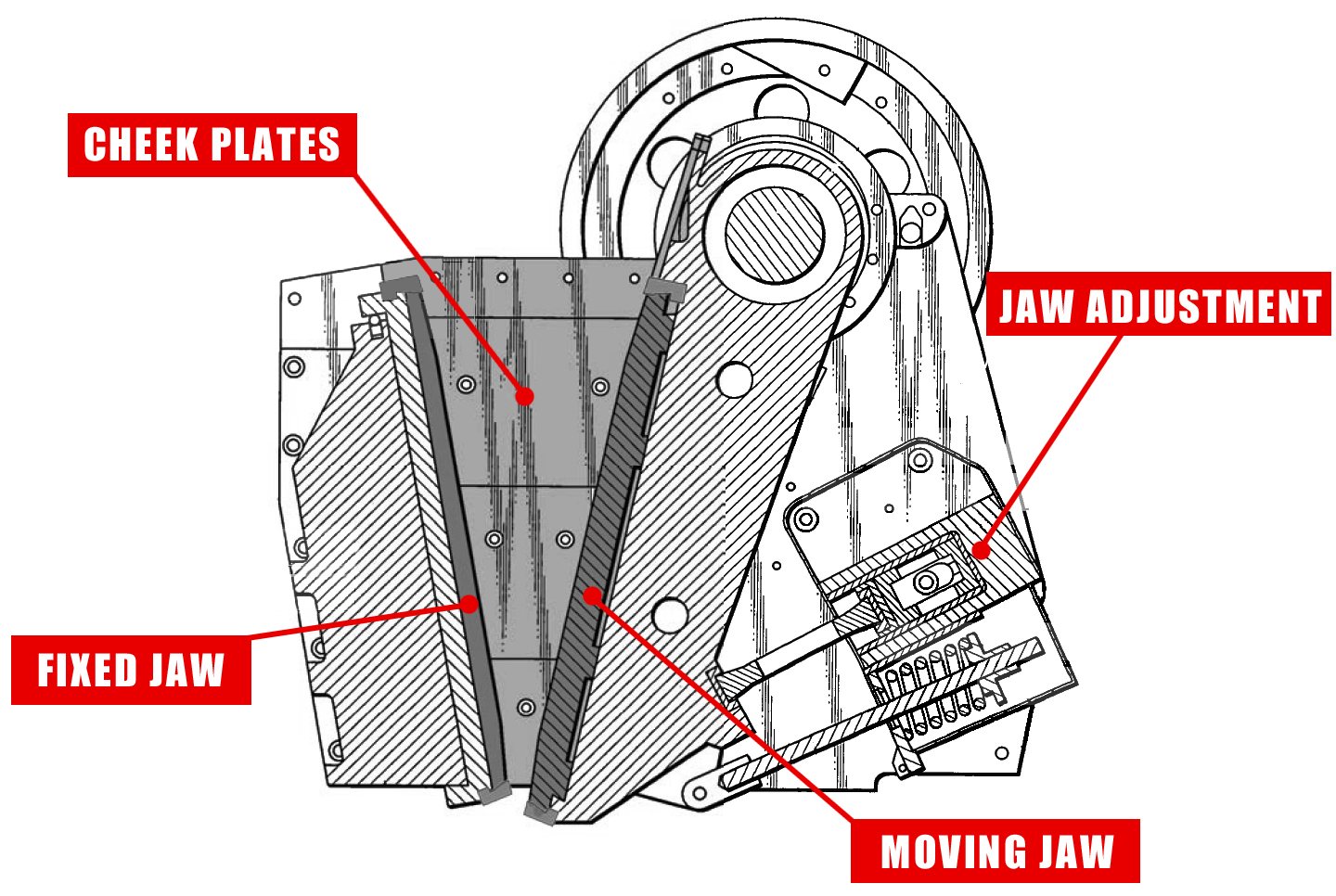

Most common jaw crushers consist of two steel plates (one fixed and one that swings) and the material is reduced, as it falls between the two, by the moving plate. These steel plates have bolt on Manganese jaw plates that are typically slow wearing.

Advantages of Jaw Crushers:

- They are the most economical crusher to operate and easiest to work on.

- They create less dust compared to other types of crushers.

Disadvantages of Jaw Crushers:

- Product reduction is less than other technologies

- Not recommended for asphalt unless below freezing temperatures.

- As a primary crusher, normally yields a coarser material than other technologies (with the exception of Small/Mini jaw crushers).

We offer new & used jaw crushers both small & large, and we are always available to assist you with the proper crusher for your specific application.

See our current selection of Jaw Crushers