Welcome to GrinderCrusherScreen we've been in the crushing and screening business since 1973, so we’ve seen just about every way crushed stone and gravel can be used and mis‑used on jobsites. Across construction and landscaping projects, getting the stone size range right is one of the easiest ways to save money, avoid callbacks, and build a stable surface that actually lasts.

In the U.S., crushed stone production is roughly 1.5 billion tons per year, with a value over 24 billion dollars, most of it ending up in roads, concrete mixes, railroad ballast, drainage systems, and residential driveways. When you understand crushed stone grades, gravel sizes, and the types of gravel available, you’re in a much better position to choose the right material for your base material, slab base, drainage solutions, and decorative landscaping needs.

What Is Crushed Stone (and How Does it Differ From Gravel)?

Crushed stone is a versatile material made from natural rock deposits limestone, granite, trap rock, or recycled concrete that are blasted, fed into jaw crushers or cone crushers, and then processed through screening equipment to create controlled stone sizes. Each grade includes stone within a defined size range, which is set by what passes through and is retained on specific screens in a gravel size chart or size chart based on AASHTO or DOT specs.

Gravel is closely related but not identical:

- Crushed stone: Angular particles with sharp edges created mechanically; this angularity builds superior stability and structural integrity under heavy loads because the pieces interlock.

- Natural gravel: More rounded stones or smooth stones formed in rivers and glacial deposits; most gravel has a smooth texture and rounded stones that can roll or shift unless strongly confined.

You’ll also hear terms like natural aggregate, crushed gravel, washed gravel, and gravel stone. These all describe aggregate, but their source, processing, and finish matter when you’re trying to build a stable foundation, drain naturally, or achieve a certain aesthetic appeal.

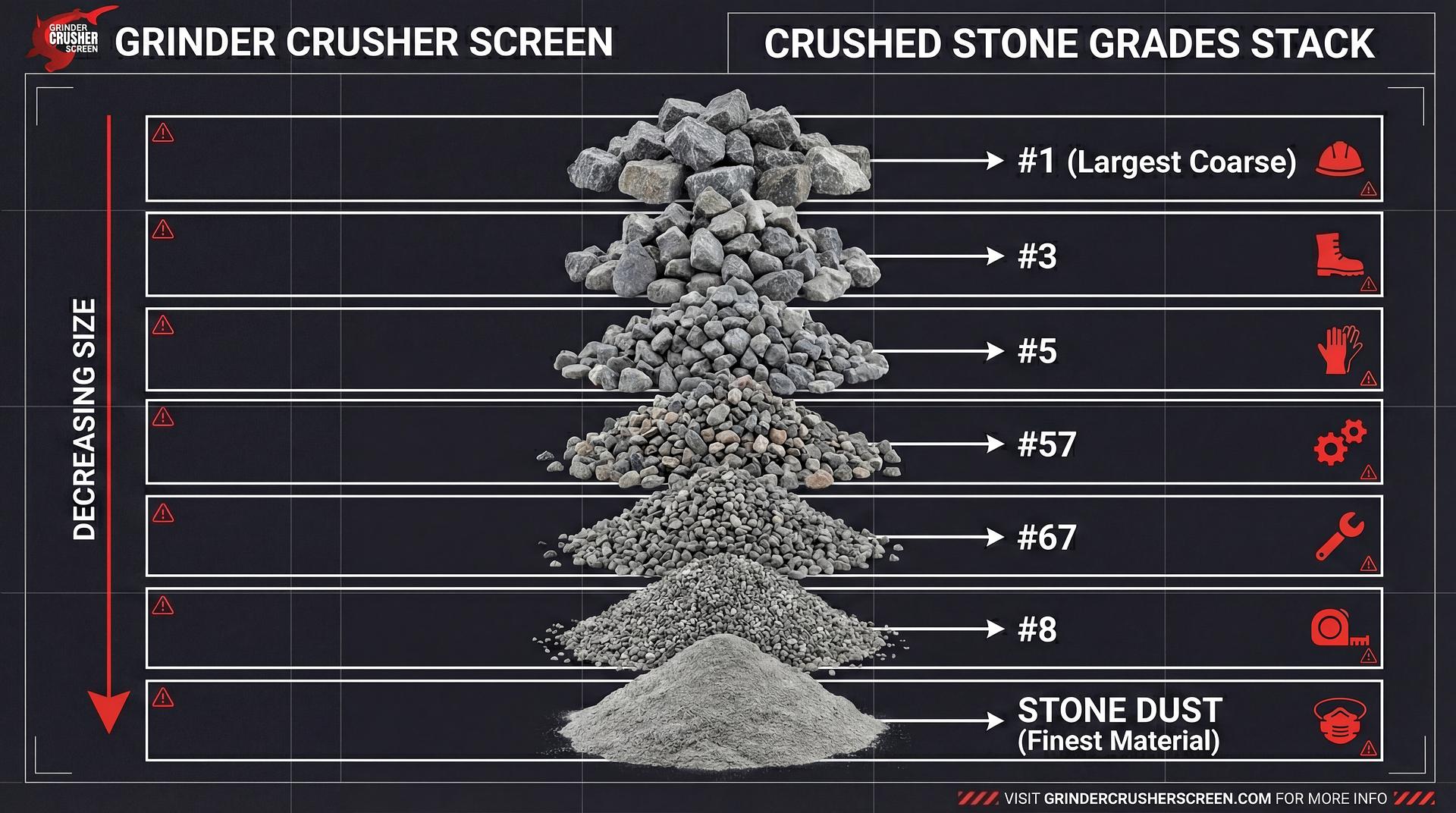

Crushed Stone Grades Explained

When contractors talk about “#57 stone,” “pea gravel,” or “stone dust,” they’re really talking about different grades and stone sizes. Below we’ll walk through the most common stone grades from coarse base material to fine material used under pavers and concrete blocks.

#1 Stone

- Typical size: About 2–4 inches in diameter.

- Best uses:

- Filling large holes and deep soft spots in construction projects.

- Sub‑base for roads and railroad projects that carry heavy loads.

- Erosion control along embankments and drainage applications where larger stones resist washout.

Because these larger stones do not compact into a smooth surface, #1 stone is more about bulk support and erosion control than finished surfaces.

#3 Stone

- Typical size: About ½–2 inches.

- Best uses:

- Railroad ballast and railroad projects where large, angular stone distributes loads and provides excellent drainage.

- Deep road and slab base layers on poor subgrade.

- Base material under parking pads, general construction projects, and areas that require drainage.

#3 stone is big enough to maintain voids for water flow but small enough to start building a stable foundation under roads and heavy equipment.

#5 Stone

- Typical size: Around 1–1½ inches, depending on local standard.

- Best uses:

- Road and paver base where you need a balance of compaction and drainage.

- Road and paver base for driveways and light commercial parking pads.

- Transitional base between very coarse #3 stone and mid‑range #57 stone.

#5 stone is a great material when you need a road and slab base that can handle traffic but still require drainage in the section.

Mid‑Range Workhorses: #57, #67 and Crusher Run

When people ask us about the “best gravel” or the right gravel for driveways, french drains, and slab base, we usually end up talking about #57 stone, #67 stone, and crusher run.

#57 Stone

- Typical size: Commonly around ¾ inch average, with a range down to about ⅜ inch.

- Spec example: AASHTO #57 is defined by what passes specific screens to control stone sizes and fines.

- Best uses:

- Residential driveways and general construction driveways that require drainage and a stable surface.

- Road and slab base under concrete mixes and asphalt where excellent drainage is needed.

- French drains, drainage systems, and backfill behind retaining walls because #57 provides excellent drainage and resists clogging.

57 stone is one of the most common stone grades in North America because it offers better drainage than finer mixes while still forming a stable foundation under vehicles and structures.

#67 Stone

- Typical size: Slightly smaller than #57, generally under ¾ inch.

- Best uses:

- Slab base under concrete blocks and poured slabs where a tighter, thinner base is needed.

- Road shoulders and thin road sections that require drainage but need tighter compaction.

- Concrete mixes that call for smaller aggregate for workability.

Compared to #57, #67 stone compacts into a smoother, denser layer, which is helpful when you need a stable surface in a limited thickness.

Crusher Run / Dense‑Grade Mixes (e.g., #411)

Crusher run is a blend that includes stone like #57 plus stone dust or screenings. A common dense‑grade product is #411, which mixes #57 stone with #10 stone dust to create a compactable base.

- Best uses:

- Paver base and paver base material under patios, walkways, and small parking pads.

- Road and paver base where superior stability and interlock are critical.

- Areas that require drainage but also need a very tight surface after compaction.

Crusher run is a great material when you want a base that locks together and resists rutting under traffic.

Finer Aggregates: Stone Dust, Fine Gravel, and Small Stone Sizes

Moving down the stone size range, you’ll find materials used for bedding, finishing, and decorative purposes.

#8 Stone and Fine Gravel

- Typical size: Roughly ⅜ inch and smaller, often considered fine gravel in many size charts.

- Best uses:

- Concrete mixes and thin asphalt lifts as a controlled aggregate size.

- Decorative landscaping and decorating landscapes around garden beds, paths, and seating areas.

- Top layers over coarser stone where a smoother, visually appealing finish is desired.

Because #8 stone is small and easy to walk on, it’s common in landscaping projects and decorative purposes that still need a stable surface.

#10 Stone (Stone Dust / Screenings)

- Typical size: Fine material and fine particles passing small screens (#10 and smaller).

- Best uses:

- Bedding for pavers and small slabs to create a stable foundation.

- Filling joints between pavers to create paver surfaces that resist movement.

- As part of crusher run blends to fill voids and increase structural integrity.

Stone dust and screenings are critical when you want to create pavers that don’t rock, settle, or lose sand over time.

Types of Gravel and Decorative Aggregates

Beyond strict crushed stone grades, there are several types of gravel that show up in both construction and landscaping projects.

- Pea gravel: Small, rounded stones that are comfortable underfoot and visually appealing; great for garden beds, walkways, and play areas when contained by edging.

- River rock: Larger, smooth stones with a rounded profile; ideal for water features, drainage swales, and decorative landscaping where natural rock deposits and smooth texture are part of the design.

- Marble chips: Bright, angular stone often used in high‑end decorative landscaping for contrast around shrubs, garden beds, and entryways.

- Lava rock: Lightweight, porous, and bold in color; commonly used in decorating landscapes and as mulch in dry climates.

These aggregates are chosen as much for aesthetic appeal as performance. They can be part of drainage applications and erosion control, but for structural work like road and slab base or parking pads, crushed stone generally does the heavy lifting.

How to Read a Gravel Size Chart (and Choose the Right Material)

A gravel size chart or stone size chart lines up each grade—like #57 stone, #8 stone, or #3 stone—with its nominal stone sizes in inches or millimeters and the screens used to produce it. Used properly, it helps you pick the right gravel or right material for each layer of your project.

Here’s how we coach customers through it:

- Clarify the application.

- Driveways, parking pads, and general construction? Look at mid‑range crushed stone like #57 and #67.

- Drainage systems, french drains, or backfill behind retaining walls? Look at open‑graded stone like #57 and larger stones that allow water to flow.

- Paver base and slab base? Look at crusher run, #57 plus stone dust, or #8 over screenings.

- Decide what you need most: drainage vs. compaction.

- If you require drainage, choose open‑graded stone with minimal fines, like #57 stone, so water can pass freely and relieve pressure.

- If you need a super tight, stable surface, use dense‑grade mixes like crusher run or #411, which blend graded stone with fine material.

- Confirm in the chart.

- Use the gravel size chart to confirm that your selected grade actually matches the stone size range and spec your engineer or code requires.

- Compare related grades—for example, 57 stone vs 67 stone—to understand why one gives better drainage and the other compacts tighter.

This process is also how you figure out how much gravel you need: once you know stone sizes, thickness, and area, you can calculate volume and tonnage and avoid under‑ordering.

Matching Stone Grades to Real‑World Jobs

Let’s connect specific crushed stone grades to typical construction and landscaping projects.

Driveways and Parking Pads

- New driveway or parking pads on soft ground:

- Base material: #3 or #5 stone to create a strong, free‑draining base.

- Intermediate layer: #57 stone for better load distribution.

- Surface: #57 stone alone, or #8 stone over #57 for a smoother, more decorative finish.

- Existing residential driveways that require drainage and resurfacing:

- Top layer: 1–2 inches of #57 stone or #67 stone to rebuild crown and improve water run‑off.

- For a very tight surface, use crusher run or #411 and compact well so traffic doesn’t pull the stone out of place.

Concrete Mixes, Slab Base, and Road Base

- Slab base and road base:

- Mid‑range crushed stone like #57 and #67 for a draining, compactable base under concrete or asphalt.

- Road and slab base may also use #3 and #5 underneath in wetter or weaker soils.

- Concrete mixes:

- Often use #57, #67, or smaller stone sizes such as #8, depending on structural design and finish requirements.

Drainage Systems and Erosion Control

- French drains and perimeter drainage systems:

- Clean #57 stone or similar washed gravel that provides excellent drainage and resists clogging.

- Erosion control and retaining walls:

- Larger stones and crushed stone backfill behind retaining walls to relieve water pressure.

- River rock or larger stones for erosion control in swales and around water features, combined with geotextile fabric where necessary.

8 Stone vs 57 Stone, and 57 vs 67 Stone

Your customers will often ask which type of gravel or crushed stone they should choose, especially in the 8 stone / 57 stone / 67 stone range.

8 Stone vs 57 Stone

- 8 stone: Smaller stone size, roughly pea gravel or fine gravel size; great for concrete mixes, thin surfacing, and decorative landscaping.

- 57 stone: Coarser, better drainage, and more load‑bearing capacity; ideal for residential driveways, road base layers, drainage applications, and slab base.

8 stone is a strong choice for finishing layers and decorative purposes, while 57 stone is a more versatile material for structural work.

67 Stone vs 57 Stone

- 67 stone: Slightly smaller and more uniform; compacts into a denser layer that’s good under thin concrete slabs or asphalt.

- 57 stone: Has a wider size range and better drainage, making it a common stone grade for driveways, french drains, and general construction bases.

In practice, 57 stone may be the common stone you use in most general construction, while 67 stone is a smart choice when you need tighter compaction with some drainage.

Equipment Perspective: Producing On‑Spec Stone and Gravel

Since we live in the equipment world, we don’t just sell aggregate—we help you produce it. With the right combination of jaw crushers, cone crushers, and screening equipment, you can turn natural rock deposits or recycled concrete into on‑spec crushed stone grades.

By choosing the right screen decks and settings, you can produce:

- #57 stone and #67 stone for base and drainage.

- 8 stone and stone dust for paver base and decorative gravel.

- Coarse stone like #3 and #5 for road and slab base and deep structural fills.

Producing your own crushed stone and gravel gives you control over quality, helps you deliver the right gravel size for each job, and turns waste into sellable material.

Bringing It All Together

Whether you’re building parking pads, residential driveways, french drains, or retaining walls, understanding crushed stone grades, stone sizes, and the types of gravel available is the key to choosing the right material for each layer.

At GrinderCrusherScreen, we’ve spent more than 50 years helping contractors pick the right equipment to match the job. If you’re not sure which stone size range you need or how to dial your crushers and screens to hit those specs reach out. The right gravel, in the right place, produced the right way, is the difference between constant maintenance and a project that works.