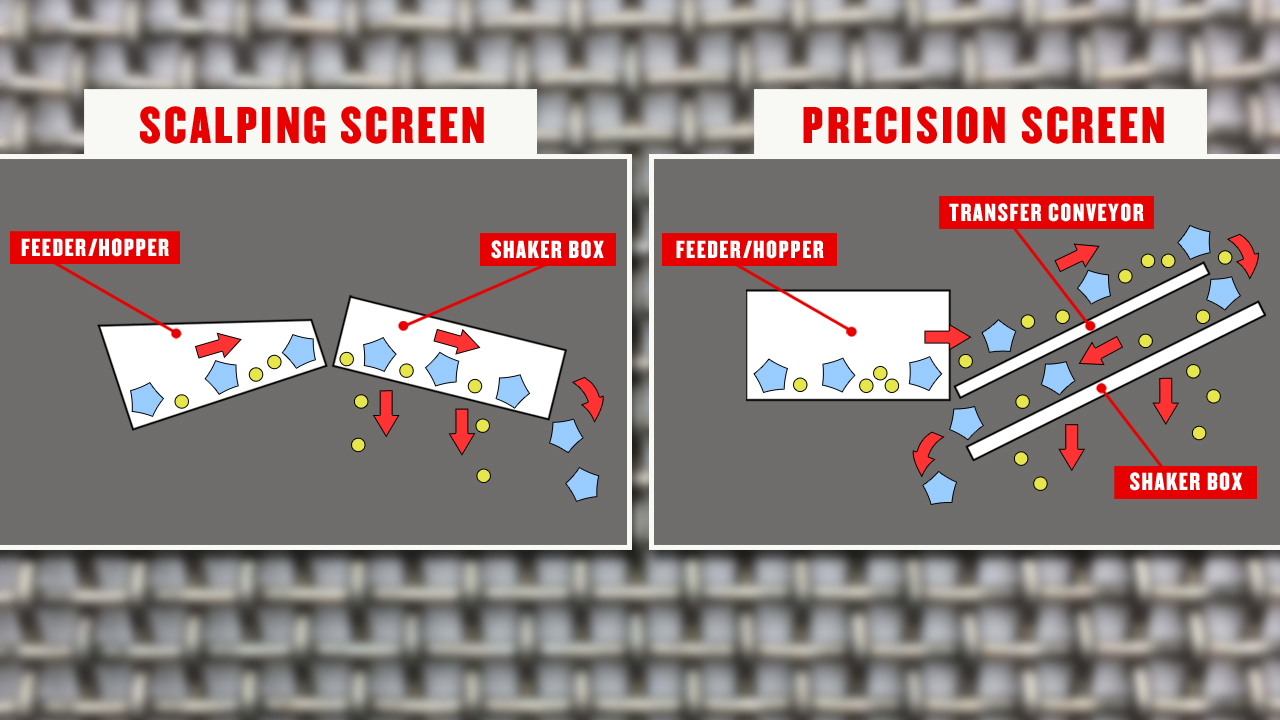

To best answer this question, we must discuss the different types of shakers typically found on portable screening equipment. The most popular screeners, Precision Screens, are typically found in sand and gravel applications, and have an eccentric shaft of 3/32” to ¼”. It is very common for the shaft to be spinning backward in these screeners and to have the shaker box set at a steep slope. To differentiate this style of screener, the feeder normally discharges onto a transfer conveyor that travels upward to the screen (which is usually parallel to the transfer conveyor). This style of screener is typically found screening aggregates and topsoil (without stringy roots).

Scalping Screens or Severe Shaker Screens are easy to spot as the material is fed directly onto the shaker box from the feeder (with the box sloped away from the feeder). The shaker box is on a slight slope with the top deck normally having a punch plate or a thick wire woven screen. The eccentric shaft is normally 3/8” to ¾” allowing for a big- time shake. The speed of the shaft is also considerably slower than those previously mentioned. Severe Shaker screens are typically for heavy-duty screening and for nasty materials. If your material has large rocks and wood, this is your best choice. Other typical applications are grub-in (which is a term for land clearing where there is root mat, rocks, wood, etc...) The “severe shake” of these screens allows for better separation and less tendency of the roots getting stuck on the screens.

GrinderCrusherScreen has the industry experts that can assist in determining which shaker screen is best for your application.

See all of our current New & Used Shaker Screen selection

Pictured on the left: The Evortle SR2512 Precision Screen, on the right: The Screen USA CD410 Scalping Screen. Both available New ONLY via GrinderCrusherScreen.