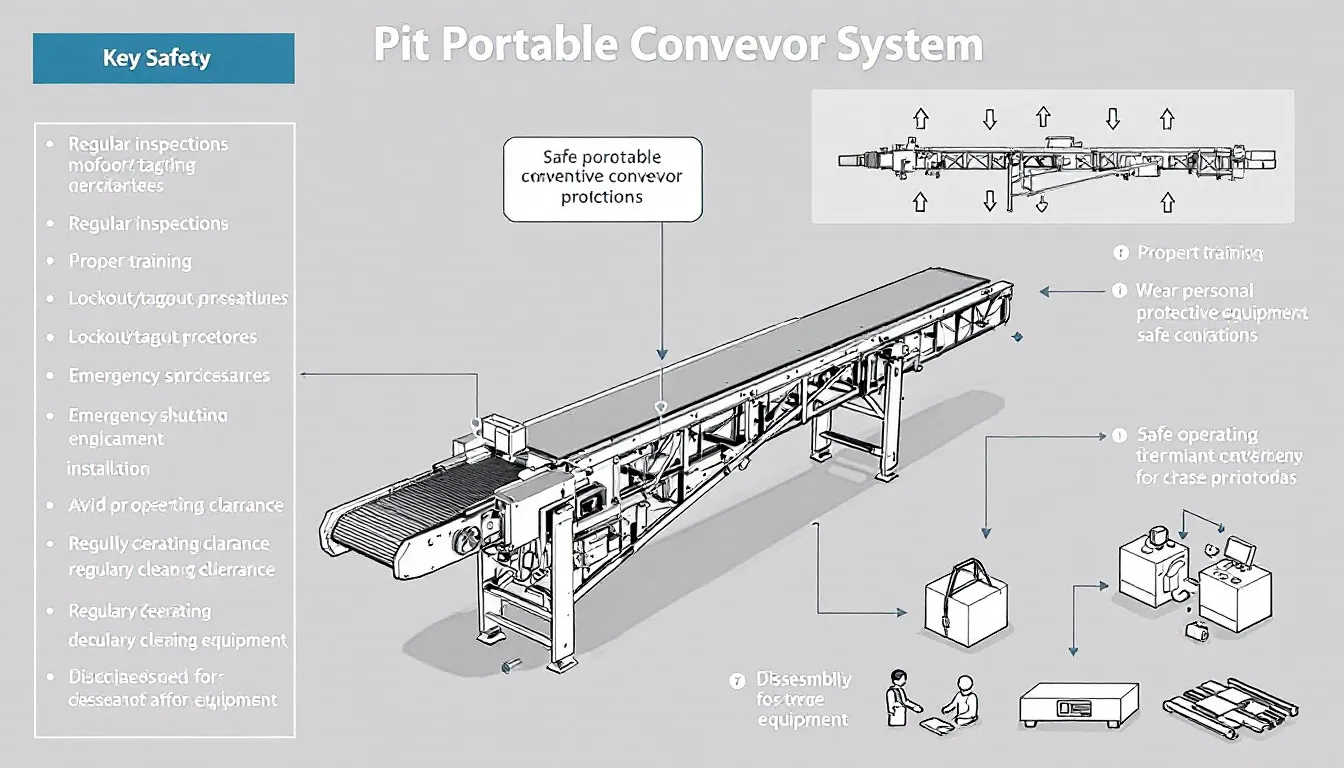

When operating pit portable conveyors, understanding the general requirements of safety regulations is critical. This article will cover key safety measures like guarding moving parts, emergency stop devices, start-up warnings, and following strict procedures. Regular training and maintenance are also essential for safe use. Understanding these aspects ensures safe and efficient conveyor operations.

Key Takeaways

- Identifying and mitigating hazards in conveyor operations is critical to ensure worker safety and regulatory compliance.

- Implementing safety measures such as guarding moving parts, emergency stop devices, and start-up warning systems is essential to prevent accidents.

- Regular maintenance, comprehensive training, and adherence to safety regulations significantly enhance overall conveyor safety and reduce risks.

Importance of Conveyor Safety in Pit Operations

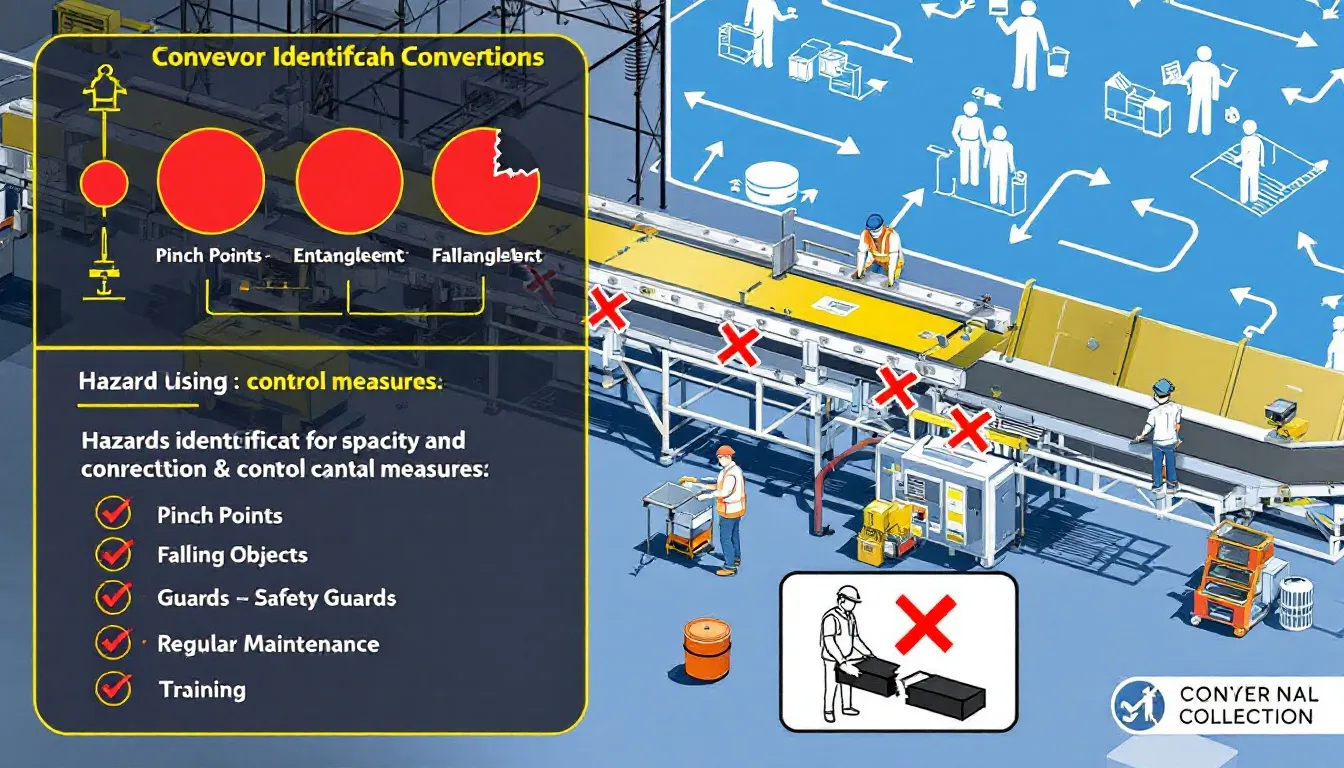

Conveyor safety is paramount in pit operations. The hazards posed by conveyor systems, such as pinch points, crush hazards, falling objects, and fall risks, are numerous and potentially lethal. Identifying these hazards is the first step towards preventing accidents and ensuring worker safety. But identification alone is not enough; effective control measures must be implemented to mitigate these risks.

Recognizing the critical nature of these risks is crucial. Conveyor belts and screw conveyors can create dangerous environments if safety protocols are not strictly followed. Having all safety measures in place not only protects workers but also ensures regulatory compliance, thus avoiding legal and financial repercussions.

Guarding Moving Parts

Protecting workers from moving machine parts of conveyors is crucial for safety. Various customizable guarding options, such as barriers and guardrails, can be tailored to meet specific safety needs. These mechanisms are vital in preventing unauthorized access and protecting workers from moving parts. Effective guards around rollers, pulleys, belts, and moving conveyor shield workers from potential harm.

Guarding strategies should incorporate barriers to prevent access to moving parts in motion. These barriers act as a first line of defense, reducing the risk of accidents around conveyors. Properly guarded mechanical machinery not only enhances safety but also fosters a safer work environment where construction workers can perform their duties without fear of injury, especially when the areas are enclosed. The guard ensures that safety measures are effectively implemented.

Emergency Stop Devices

Emergency stop devices are essential in conveyor systems. OSHA standards require that these devices be easily equipped and accessible to enhance worker safety and prevent failure.

If any part of a conveyor is not visible from the starting controls, an alarm system must be installed to alert individuals to the moving parts, emphasizing the importance of safety measures in preventing accidents and ensuring compliance with standards.

Here are some key points regarding emergency stop devices:

- Emergency shut-off buttons and pull cords provide immediate response capabilities in hazardous situations.

- They allow for quick cessation of conveyor operation to prevent accidents.

- Placing these emergency controls for quick access ensures prompt use during emergencies.

By adhering to these guidelines, you can significantly improve safety in conveyor operations.

Routine maintenance checks should include verifying the functionality of emergency stop devices to ensure they are operational when needed. This includes testing the emergency controls and ensuring that all safety devices are in working order. Incorporating these checks into regular maintenance schedules significantly reduces the risk of accidents and enhances safety repairs.

Start-Up Warning Systems

Start-up warning systems are vital for alerting workers before a conveyor begins operation. These conveying systems are designed to notify personnel to clear the area, thereby reducing the risk of accidents significantly. Effective warnings systems include audible alarms and visual signals that alert workers of impending conveyor movement, especially in areas with limited visibility.

Start-up warning systems proactively enhance safety by preventing accidents before they occur. By ensuring that workers are aware of when a conveyor starts, these systems contribute to a safer work environment and help in maintaining smooth and accident-free operations.

Safe Operating Procedures for Pit Portable Conveyors

Safe operation of pit portable conveyors requires strict adherence to established protocols. These protocols mitigate the inherent risks of conveyor operations. Essential procedures include conducting pre-operation checks, ensuring safe loading and unloading practices, and maintaining equipment regularly. Regular audits and inspections are also crucial to ensure compliance with safety regulations and to identify potential hazards.

Safe operation of pit portable conveyors requires strict adherence to established protocols. These protocols mitigate the inherent risks of conveyor operations. Essential procedures include conducting pre-operation checks, ensuring safe loading and unloading practices, and maintaining equipment regularly. Regular audits and inspections are also crucial to ensure compliance with safety regulations and to identify potential hazards.

Ensuring safe access with proper walkways and guardrails is essential to prevent slips, trips, and falls during maintenance activities.

Adhering to these procedures is not just about compliance; it creates a safer work environment for everyone. By following these guidelines, operators can significantly reduce the risk of accidents, ensuring that conveyor systems function effectively and safely.

Pre-Operation Checks

Pre-operation checks are crucial for conveyor safety. Before starting the conveyor, operators must confirm that all safety devices and emergency stop mechanisms are functional. Regular maintenance and inspections help identify potential hazards and ensure that the conveyor can operate in good working condition. Thorough pre-operation checks significantly reduce the risk of accidents and promote safety.

Additionally, lubrication points should be easily accessible during these checks to ensure worker safety and prevent accidental contact with moving machine parts.

These checks should verify that all guards are secure, examine the conveyor for loose parts, and ensure proper alignment. By taking these precautions, operators can repair potential issues before they escalate into serious problems, thereby enhancing overall safety.

Safe Loading and Unloading Practices

Safe loading and unloading practices prevent material handling accidents in hazardous areas. Designating areas for these activities minimizes the risk of accidents. Lifting load materials at designated stations ensures a controlled process that loads materials safely.

Using chutes as a type of gravity conveyor can facilitate safe loading and unloading practices by efficiently moving materials and supplies within work sites and between workstations.

These practices not only enhance safety but also improve efficiency. By having clear procedures for loading and unloading, operators can ensure that materials are handled safely and that the risk of injuries is reduced. These practices are a key component of a comprehensive conveyor safety strategy.

Regular Maintenance and Inspections

Regular maintenance and inspections ensure conveyor safety. OSHA emphasizes the importance of these practices, highlighting that regular checks help keep conveyor systems functioning effectively and extend their operational lifespan. The Lockout/Tagout (LOTO) standard is particularly important as it prevents unexpected startups during maintenance, ensuring worker safety.

For example, regular inspections of a screw conveyor, a mechanical device consisting of a trough and a revolving shaft with a spiral or twisted plate, are crucial. Ensuring the mechanism and connections are enclosed and safeguarded during loading and unloading materials is essential for safety.

A consistent maintenance schedule helps detect wear and tear that could compromise safety. Frequent checks on drive components and belt alignment are necessary to minimize wear and ensure optimal performance. Adhering to these maintenance practices significantly enhances the safety and efficiency of conveyor systems.

Hazard Identification and Control Measures

Hazard identification and control are cornerstones of conveyor safety. Pre-operation checks help identify potential hazards that could lead to accidents. Inspecting conveyors for issues such as loose parts and proper alignment is essential before starting operations.

Hazard identification and control are cornerstones of conveyor safety. Pre-operation checks help identify potential hazards that could lead to accidents. Inspecting conveyors for issues such as loose parts and proper alignment is essential before starting operations.

Addressing safety issues through regular maintenance and compliance with safety regulations is crucial. Neglecting these can lead to various hazards, making it important to identify and resolve them promptly to ensure safe and efficient functioning.

Effective measures include secured guards and functional safety devices and emergency stops. Adhering to these measures mitigates risks and reduces the likelihood of accidents.

Identifying Nip Points

Nip points are critical danger areas on belt conveyors. These location points, typically between the conveyor belt and pulleys or rollers, can trap and injure workers. Conveyors are inherently dangerous due to nip points and other moving parts.

Proper guarding of nip points prevents accidents. Inadequate protection at these locations can lead to severe injuries. Identifying and guarding nip points significantly enhances safety and protects workers. Additionally, keeping conveyor belts clean to prevent materials from falling to the ground is crucial, as debris on the ground can pose hazards to workers and complicate maintenance efforts.

Implementing Safety Devices

Safety devices are essential for preventing accidents in conveyor operations. Here are some key devices:

- Emergency stop buttons

- Pull cords, which are vital for quickly halting conveyor operation to prevent accidents

- Automatic sensors that detect blockages or equipment failures, enhancing safety by stopping the conveyor before hazards cause injury

Additionally, ensuring that the connections to the power source of screw conveyors are properly enclosed is crucial for safety. Safeguarding measures are essential when operating these machinery components to prevent any accidents related to the power source.

The use of sensors and other safety devices not only prevents accidents but also fosters a culture of safety awareness among workers. Equipping conveyors with these safety mechanisms ensures system safety and worker protection.

Proper Use of Personal Protective Equipment (PPE)

Proper use of Personal Protective Equipment (PPE) is fundamental to conveyor safety for each person. Safety glasses protect eyes from debris, while gloves protect hands from cuts and abrasions. Hearing protection is necessary for workers in noisy environments to prevent long-term hearing damage.

Additionally, appropriate footwear is vital to protect against slips and injuries, and long hair should be secured to prevent entanglement in moving parts of the conveyor. OSHA mandates employers to assess workplace hazards and provide appropriate PPE for their workers. Ensuring all personnel use necessary PPE significantly enhances safety.

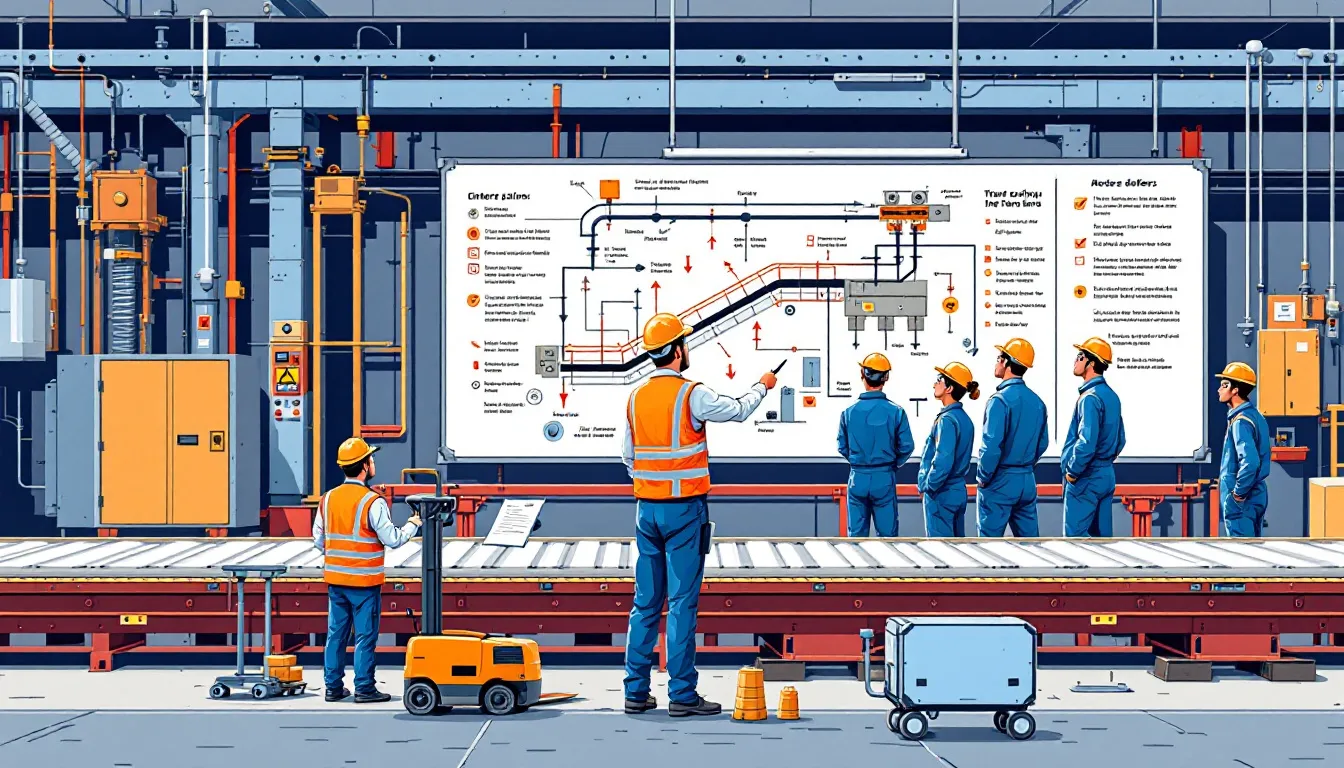

Training and Supervision

Training and supervision are crucial for conveyor safety. Comprehensive training programs ensure employees understand potential hazards and manage them effectively. These programs also enhance employee awareness of safe practices and regulations related to conveyor operations.

Training and supervision are crucial for conveyor safety. Comprehensive training programs ensure employees understand potential hazards and manage them effectively. These programs also enhance employee awareness of safe practices and regulations related to conveyor operations.

Equally important is supervision by experienced personnel. Supervisors play a crucial role in ensuring that conveyor operations are conducted safely and in compliance with safety guidelines. Combining effective training with experienced supervision creates a safer work environment and reduces the risk of accidents.

Comprehensive Training Programs

Comprehensive training programs enhance conveyor safety. MSHA mandates regular training for employees to prevent accidents and injuries. These programs should cover operational procedures, maintenance practices, and emergency response protocols to ensure safety.

Training should include practical demonstrations for safely operating conveyors and addressing emergency situations. Thorough training ensures employees are well-prepared to handle any hazards.

Experienced Supervision

Experienced supervision ensures safe conveyor operations. Supervisors with thorough knowledge of conveyors can guide operators effectively and ensure compliance with safety guidelines. They also play a key role in overseeing loading and unloading operations to prevent accidents and ensure safe material handling.

Easy access to supervisors and open communication create a safer work environment. Experienced supervisors enhance safety and contribute to overall efficiency.

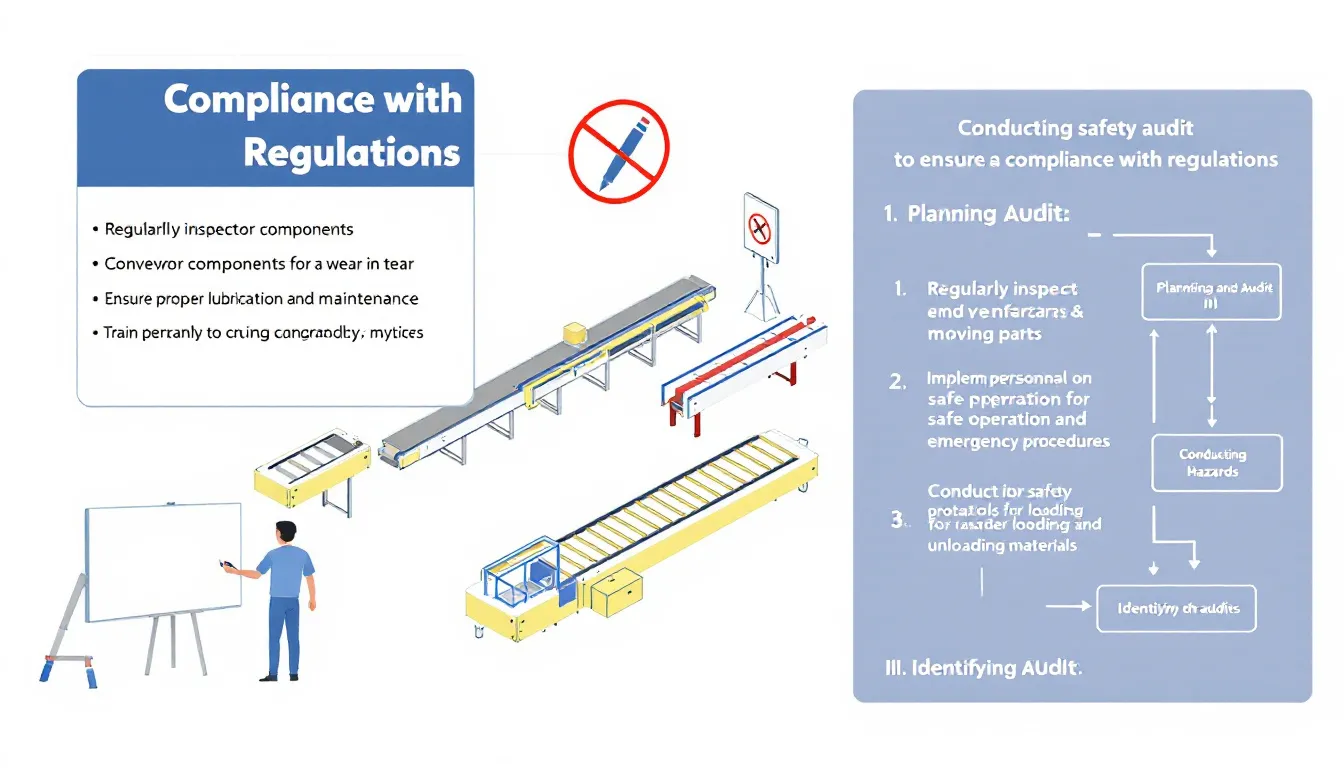

Compliance with Regulations

Regulatory compliance is vital for conveyor safety. Key regulations that cover conveyor safety include 29 CFR 1926.555, 29 CFR 1910.147, and 29 CFR 1910.212. These regulations provide guidelines on guarding and safety measures for conveyor systems, helping to mitigate legal, financial, and reputational risks.

Regulatory compliance is vital for conveyor safety. Key regulations that cover conveyor safety include 29 CFR 1926.555, 29 CFR 1910.147, and 29 CFR 1910.212. These regulations provide guidelines on guarding and safety measures for conveyor systems, helping to mitigate legal, financial, and reputational risks.

Gravity conveyors utilize the natural force of gravity to transport objects, making them an efficient and convenient option in various work environments.

Supervision by knowledgeable personnel helps maintain compliance with these regulations. Training employees about applicable regulations improves safety and ensures legal compliance.

Adhering to MSHA Standards

Adhering to MSHA standards is essential for conveyor safety. These standards include specific requirements on guarding and safety measures for conveyor systems used in mining. OSHA’s General Industry Standard also requires guards to protect workers from moving parts and pinch points.

Following these standards ensures conveyor systems are safe and compliant. This not only enhances safety but also helps in avoiding potential legal issues.

Understanding AS/NZS 4024.3611:2015

Understanding AS/NZS 4024.3611:2015 ensures the safety and efficiency of belt conveyors in bulk materials handling. This standard provides comprehensive recommendations for the design and operational safety measures that must be implemented to protect workers.

Adhering to these guidelines ensures conveyor systems are designed and operated safely, reducing the risk of accidents and enhancing efficiency.

Summary

Ensuring the safety of pit portable conveyors is a multifaceted task that requires attention to detail and strict adherence to safety protocols. From guarding moving parts to implementing emergency stop devices and conducting regular maintenance, each aspect plays a crucial role in preventing accidents and ensuring smooth operations,,.

By prioritizing safety through comprehensive training programs and experienced supervision, operators can create a safer work environment for all,. Compliance with regulations and understanding standards like MSHA and AS/NZS 4024.3611:2015 are also vital for maintaining safety and avoiding legal issues,. Remember, a safe conveyor system is not just about compliance; it’s about protecting lives and ensuring the longevity of your operations.

Frequently Asked Questions

Why is conveyor safety so important in pit operations?

Conveyor safety is essential in pit operations to prevent accidents and ensure worker safety by managing risks such as pinch points and crush hazards. Ensuring safety compliance not only protects employees but also maintains operational integrity.

What are nip points, and why are they dangerous?

Nip points are dangerous areas where conveyor parts can entrap and injure workers, particularly at the junction between the conveyor belt and pulleys or rollers. Effective guarding of these points is crucial to ensure worker safety and prevent serious accidents.

How do emergency stop devices enhance conveyor safety?

Emergency stop devices enhance conveyor safety by allowing for immediate cessation of operation during hazardous situations, effectively preventing accidents. Ensuring these devices are easily accessible and well-maintained is crucial for optimal safety.

What are some key elements of a comprehensive training program for conveyor operators?

A comprehensive training program for conveyor operators must include operational procedures, maintenance practices, and emergency response protocols. Incorporating practical demonstrations of safe operation is essential for effective training.

What standards and regulations must be followed to ensure conveyor safety?

To ensure conveyor safety, it is essential to adhere to regulations such as 29 CFR 1926.555, 29 CFR 1910.147, and 29 CFR 1910.212, alongside MSHA standards and AS/NZS 4024.3611:2015. Compliance with these guidelines is crucial for safeguarding personnel and avoiding legal issues.